Have you ever wondered how Amazon’s large distribution centres work smoothly? Amazon is one of the biggest automated warehouses, where robots and humans work together to fulfil a large number of orders.

A remarkable combination of robotics, AI-powered systems, and autonomous vehicles is making warehouse automation gain strong popularity in the market. Warehouse operation automation is slowly emerging as an evolutionary step towards upgrading supply chains and driving business growth. It does not only depend on technology upgrades; it is also a huge shift in the business approach to inventory management, order fulfillment, and supply chain improvement.

Automation technologies are redefining what’s possible in warehouse operations and it is positively impacting the growth of ecommerce marketing. Also, it is rapidly increasing customers’ expectations for urgent deliveries of products. Automation provides a compelling solution to meet these expectations by streamlining processes and reducing errors.

However, there are still some unsaid factors about warehouse automation that businesses must consider. These include the initial investment costs and the need for employee training. So, we’ve put together an in-depth guide to help you understand in-depth facts about automation in warehouses.

What is Warehouse Automation?

Automation in warehouse operation refers to a method that implements multiple advanced technologies and automated systems to improve workflows and boost productivity in a warehouse environment. As businesses aim to improve customer satisfaction, reduce errors, and increase efficiency, the adoption of automated warehouse systems is becoming increasingly popular.

Full warehouse automation involves automating many different parts of the business, such as software systems, data capture, storage and retrieval, and more. With automation, organizations use less manpower to reduce errors, improve efficiency, and more.

How do Automated Warehouses Work?

Warehouse automation encourages an improvement in storage and goods management with minimal human interference. Automation works with several internal features to manage and perform tasks seamlessly.

Let’s understand how this automation works:

Receiving & Moving Product

Goods that arrive in warehouses are equipped with barcode scanners or RFID tags that are scanned by an automated system. With this, accurate tracking of incoming products is ensured. The products move onto integrated conveyor belts, robotic arms, or autonomous mobile robots (AMRs) to categorize and sort items based on predefined criteria. These AMRs have advanced technology, so for moving products in the warehouse, they use predefined paths.

Storage Of Goods

Once the goods are received in the warehouse, the next task is to store them in the right location. Through the Warehouse automation system (WMS), goods are placed at the right location. WMS analyzes the size and weight of the products and puts them in the right storage.

Order Processing & Selection

After receiving orders from customers, AMRs, robotic arms, or human workers start retrieving the goods from storage for packing. Before packing the orders, AI scans the product to ensure the right goods are selected for delivery.

Packing & Tagging the Products

Arm robots or machines pack and label all the orders to streamline the process. With such systems, human errors are reduced, and packing is completed in less time. Arm robots and machines ensure uniform and high-quality packing for the products.

Goods Shipping & Dispatch

The sortation system in warehouse automation helps in dispatching the orders based on their delivery locations. Such transport solutions and the load planning systems in the warehouse make sure that items are loaded onto delivery vehicles in an organized manner, and the dispatch process starts on time.

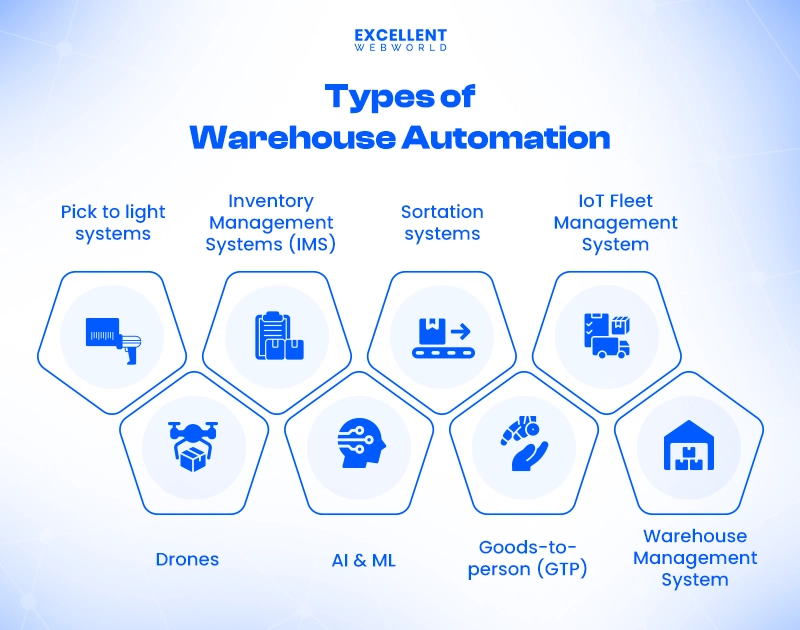

What are the Different Types of Warehouse Automation?

Warehouse automation includes various types of technologies and systems to improve the productivity of operations. However, automated systems can be physical or digitalise, wherein physical automation means the equipment for the movement of goods, such as robots or vehicles. Digital automation involves tracking, warehouse management systems, etc. There are several warehouse automation systems available that help in reducing the need for human labor. Know some of the primary categories of automation

Pick to Light Systems (PTL)

In the warehouse, to pick and collect orders workers use pick to light system. The system helps employees through light to locate the place of the item. First, workers scan the barcode available on the carton and then, with the assistance of PTL locate the right place of the item. PTL reduces errors in order picking.

Inventory Management Systems (IMS)

An automated warehouse basically depends on an inventory management system (IMS) or RFID inventory management to track all goods in real-time. IMS helps in location tracking and managing all the stocks and movement within the warehouse. At the same time, RFID (Radio Frequency Identification) tracking system lets users access detailed information using electromagnetic fields.

Sortation Systems

To enhance operations, warehouses use a sortation system. However, it benefits sorting and packaging, reducing labor costs, improving product sortation accuracy, etc. The sortation systems consist of three major components: conveyor belts, item identification systems(IDS), and separators. Conveyor belts move the product into the warehouse. In IDS, through barcodes, items are identified, and separators are in form in the form of a sliding shoe sorter or a plastic separator.

Automated Storage and Retrieval Systems (ASRS)

In the warehouse automation management system, to store and retrieve goods from high-shelving units, automated storage and retrieval systems are available. These ASRSs can be cranes or robots that help make perfect spaces and increase efficiency in moving, storing, and retrieving all the products more quickly.

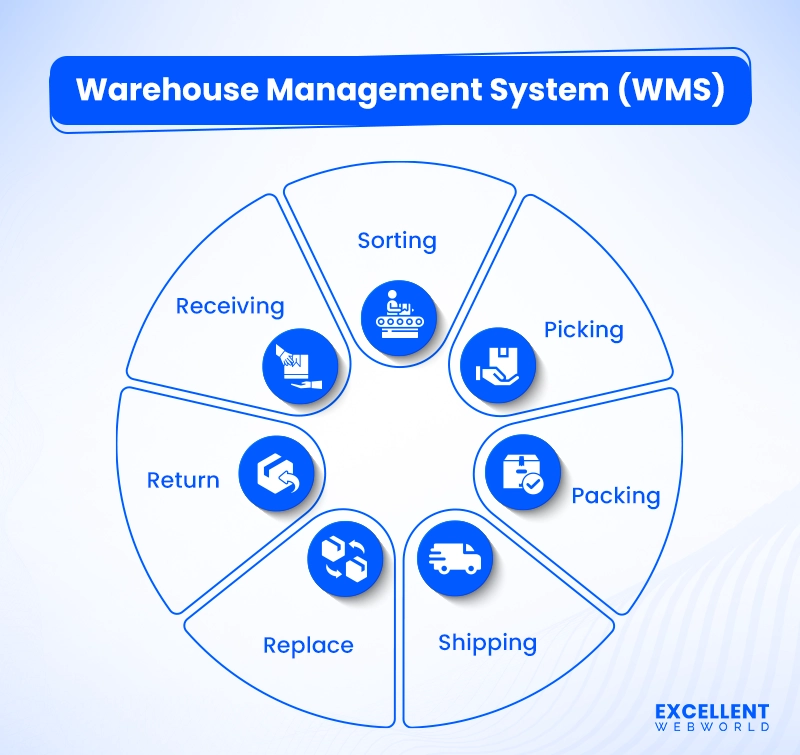

Warehouse Management System

To track all the warehouse goods and processes, a software “Warehouse management system” is used. This software has all the information about the assets that are entering and leaving the premises. WMS assists in enhancing the security system, checking the real-time inventory, balancing the workflow, and improving the customer experience.

Drones

Drones quickly scan the warehouse through barcode scanners and provide real-time data for inventory. It not only assists in rapid data collection but the cost of labor is reduced and provides better resource management.

Goods-To-Person

Good-to-person(GTP) is a product-moving automation system that all the warehouse adapts to reduce labour costs and improve efficiency. GTP automation system delivers every product directly to workers. It saves travel time and manually searching for products from the worker’s end. It also helps improve space utilization within the warehouse area and also helps in boosting warehouses to handle higher order volume.

Artificial Intelligence and Machine Learning

In warehouse automation, artificial intelligence and machine learning help with several things. With AI-based apps and ML, it is easy to predict demand in inventory while fulfilling the customer demand without overstocking. Also, through advanced data analysis efficiency of overall warehouse operations can be increased.

IoT Fleet Management System

For timely deliveries of products and tracking products in real-time, IoT fleet management systems are used in warehouse automation. It works on sensors and connectivity to track and monitor the movement of warehouse vehicles. Apart from product locating and managing a company’s fleet of vehicles, fleet management technologies help improve operational efficiency within the warehouse.

10 Key Benefits of Warehouse Automation

Shifting from a manual warehouse to an automated one is a huge change for both organizers and customers. Warehouse automation companies gain several advantages from this shift. Here are some of the advantages of automation in the warehouse brings on the table:

1. Improved Efficiency and Speed

Automation in the warehouse leads to a reduction in the processing time of orders. It means with warehouse automation all the products can be picked, packed, and shipped in less time. Also, it will help in accelerating the deliveries.

2. Reduced Operational Costs

Automation will help in cost saving by reducing labour costs and error-related costs. With automation, not only will organizers need less labour, but they will also minimize expenses associated with errors. It directly affects order returns and corrections.

3. Reduced Error Rate

The implementation of automation in warehouses improves order accuracy by reducing the chances of errors made by humans. From picking up the order to dropping them off in the meantime, automation provides error-free workflow.

4. Increased Warehouse Productivity

With automated systems, warehouses don’t need the demand for high labour. As order size increases in warehouses, with automation it becomes easy to handle the high level of workload. Organizers can also maintain productivity with less manpower.

5. Safe and Reliable Operation

Warehouse automation increases the safety standards in comparison to manual ones. With advanced technologies, the need to handle large and heavy items manually is replaced by warehouse automation robots. Also, workplace injuries are reduced rapidly.

6. Maximized Space Utilization

Businesses can optimize their warehouse space, by implanting automated storage and retrieval systems. Moreover, Organizers can spare more space for goods and other inventories in limited space.

7. Improved Inventory Management

Automation in warehouses leads to improvement in the inventory management system. With IMS, organizers can track real-time inventory and easily manage the stock level in warehouses. Also, it helps in managing the product’s availability when they are needed.

8. Strengthen Customer Satisfaction

With faster processing in warehouses, the deliveries are on time. Besides, the chances of errors in delivery are reduced, which eventually increases customer satisfaction. Timely deliveries and error-free process will increase the repeat of your buyers.

9. Long-term Sustainability

Warehouse automation is helpful in long-term sustainability. With the use of advanced technology, organizers can streamline operations while maintaining the environment’s goals. Automation contributes to creating a more sustainable supply chain.

10. Fast Scale-up

Market conditions are always changing and it affects the product demand rates. At the time of a surge in demand for products, organizers can easily manage the business to work on operations faster. Overall warehouse organizers can seize growth opportunities with automation.

How to Implement Warehouse Automation?

To initiate the implementation of warehouse automation there are a few important processes that an organizer needs to follow. Let’s understand every step in detail:

Step-1: Initial Planning and Assessment

First thing first, before delving into warehouse automation, it’s important to conduct thorough research of the market. For this, an organizer needs to work on a few important points, such as the requirements of the organization, the area for automation, and the current workflow. Make an initial plan for the warehouse automation and include present challenges with the warehouse.

Step-2: Choosing the Right Automation System

Selecting the right automation system is a critical step. Before picking any automation, analyze various tools/platforms or consult with a logistics software development company. Also, check for the scalability of the automation solutions and ensure it will help in the growth of the organization. Apart from that, consider support services and vendors’ reputations for safe workflow. Some important automation techs are:

Step-3: Integration with Existing Infrastructure

When done with the selection of the automation system plan for connecting a new system or tool with the existing infrastructure. It will help in improving the efficiency and reduce the cost. Also, it can help in developing the details about potential risks and challenges that may occur in the future.

Step-4: Employee Training and Change Management

To start and successfully run the warehouse automation, it is important to invest in employee training. It helps the staff understand the new automation system and functionalities. Along with this, necessary changes in the management system are also crucial. Organizers should focus on creating a culture that embraces innovation, encouraging employees to participate actively in the automation journey.

Challenges of Warehouse Automation

Switching from manual to automated is a step towards a tech-driven world, but it comes with numerous challenges. Including:

Initial Capital Investment

Executing warehouse automation requires a hefty amount of upfront investment. New pieces of equipment and technologies like automated storage, robotics, conveyor systems, software solutions, etc, cost very high. Medium and small-sized enterprises can struggle with securing the necessary funding.

Inventory management

Automation in inventory management is very important but it can be very difficult to manage. Organizers need to make sure that IMS is working properly and track everything accurately. For tracking products accurately RFID inventory management is a good option to track and manage inventory. Poor management of IMS can be harmful to stocks as it may lead to insufficient inventory or overstocked products.

Technical Complexity and Maintenance

In automation, the biggest problems come with technicality and maintenance. It can be challenging for companies to understand the problems related to software and hardware. However, to keep all things in line regular checking of the system and software is necessary.

Inadequate Order Management

For customer satisfaction, proper order management is very important. When it comes to automation, the processing is very easy but technical or any fault in the system proves bad. The supply chain can lead to delays or more chances of occurring errors are possible, which can directly affect service quality.

Workforce Adjustment

While shifting to automation it is important to give proper training to the employees. A lack of knowledge can be a disaster for them, as adapting to new technologies is not easy. Also shifting from manual labor can bring loss of jobs for many employees as most of the tasks are automated.

Scalability

Balancing scalability with upfront investment is a tough process. Undoubtedly, automation improves the performance of warehouses, but growth plans are the main concern. Evaluation of the Warehouse Growth Plan is important.

Item Damaging

Automation enhances many operations, but if it is not properly monitored, then it may lead to several damages. To minimize the loss organizations should invest in robust quality control measures so that they can protect inventory. It will also help minimize loss during handling and storage processes.

Quality Control

For customer satisfaction and the image of the company, maintaining quality standards is very important. However, while running a huge warehouse automation system, at some point quality control can be an issue. Failure to implement rigid quality control can result in defects in shipping products or lead to costly returns.

Future of Warehouse Automation

Future warehouse automation will enhance several aspects of operations and will give a boost to customer satisfaction. With automation, warehouses will see a huge change in the increase of accuracy and speed of the work. Let’s understand some of the key aspects of future automation:

Efficient And Flexible

An increase in e-commerce is giving rise to warehouse automation companies. To fulfil the increasing demand of customers, warehouses are moving towards advanced automation systems. With advanced technologies, human errors will be minimized,d and accuracy in right and on-time product deliveries will be increased. Moreover, flexible automation solutions allow warehouses to adapt to changing order volumes without significant downtime.

Trends and Emerging Technologies

For future warehouse automation, adopting AI and ML will be very beneficial. Combining them will help in the analysis of inventory management, managing stock levels of warehouses, and improving demand forecasting. Along with this, for real-time tracking and monitoring of products and operations, IoT for logistics warehouse automation will play an important role. Emerging technologies will enhance productivity without having a lot of human workforces.

The Role of 5G And Autonomous Mobile Robots

When we are discussing future Autonomous Mobile Robots will be one of the most important operational parts of warehouses. From managing orders within the warehouse to picking and packing orders with minimum errors, everything will be automated by mobile robots. On the other hand, 5G technologies will help with faster connectivity of data transmission. This connectivity facilitates the seamless integration of automation technologies, which will ultimately result in more efficient workflows.

Green Warehousing

After vehicles now warehouses will be going green to reduce their carbon footprint from the market. By adopting green technologies, warehouses will adopt energy-efficient systems. For example, renewable energy sources, eco-friendly materials, etc. Moreover, this practice for warehouses not only helps towards environment but will help in cost reduction on electronics.

Explore Our Warehouse Automation Solutions

Adapting automation in warehouses can be challenging as you need to switch from manual to automated technologies. However, you can always get help from an expert to streamline your warehouse operations.

We can help you start your warehouse automation through AI-based technologies. From automated inventory management systems to real-time data analytics, our developers can help you build customized software solutions. Don’t hesitate to reach out, contact us today to explore how we can fulfil your warehouse automation strategy!

Request your consultation now!

FAQs

Automated warehouse process operations with the help of technologies and minimal human resources. In such warehouses, from managing inventory to packing products, technologies are available to streamline processes.

Warehouse automation has three levels: Basic automation, System Automation, and Advanced Automation.

A fully automated warehouse processes all the operations with an advanced automation system, from picking and sorting products to managing inventory systems.

The future of warehouse automation will use advanced AI and ML technologies to streamline operations processes. IoT devices will be used to track inventory in real-time, data collection, and enhance the performance of warehouse operations.

Article By

Mayur Panchal is the CTO of Excellent Webworld. With his skills and expertise, He stays updated with industry trends and utilizes his technical expertise to address problems faced by entrepreneurs and startup owners.